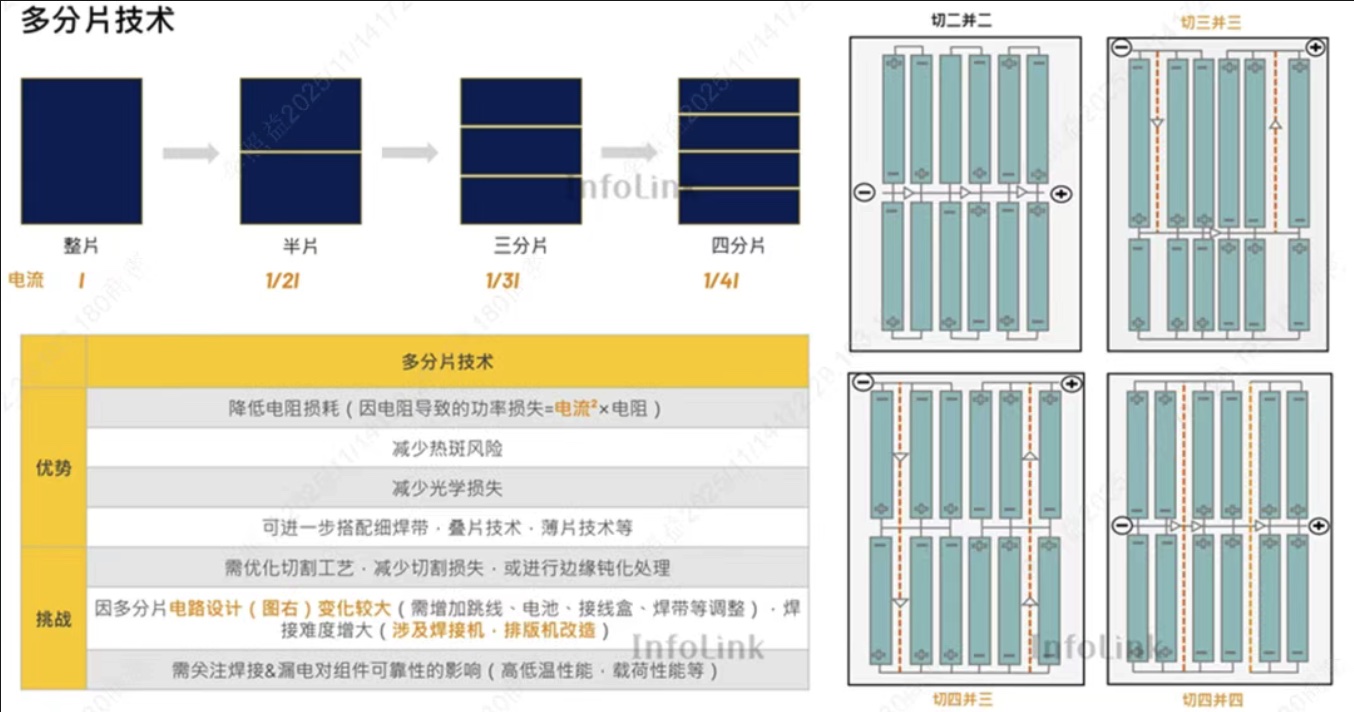

Today we'll discuss quadruple-cut PV modules. This represents the latest evolution in technological competition, and by 2026, triple-cut and quadruple-cut modules may become ubiquitous across PV manufacturing facilities. The emergence of quad-cell technology has boosted the power output of individual modules by 15-20W overall, reducing the cost per kilowatt-hour by an additional 1.82%. However, this is far from a simple three-cut process; it represents a critical battle concerning technological barriers and cost control.

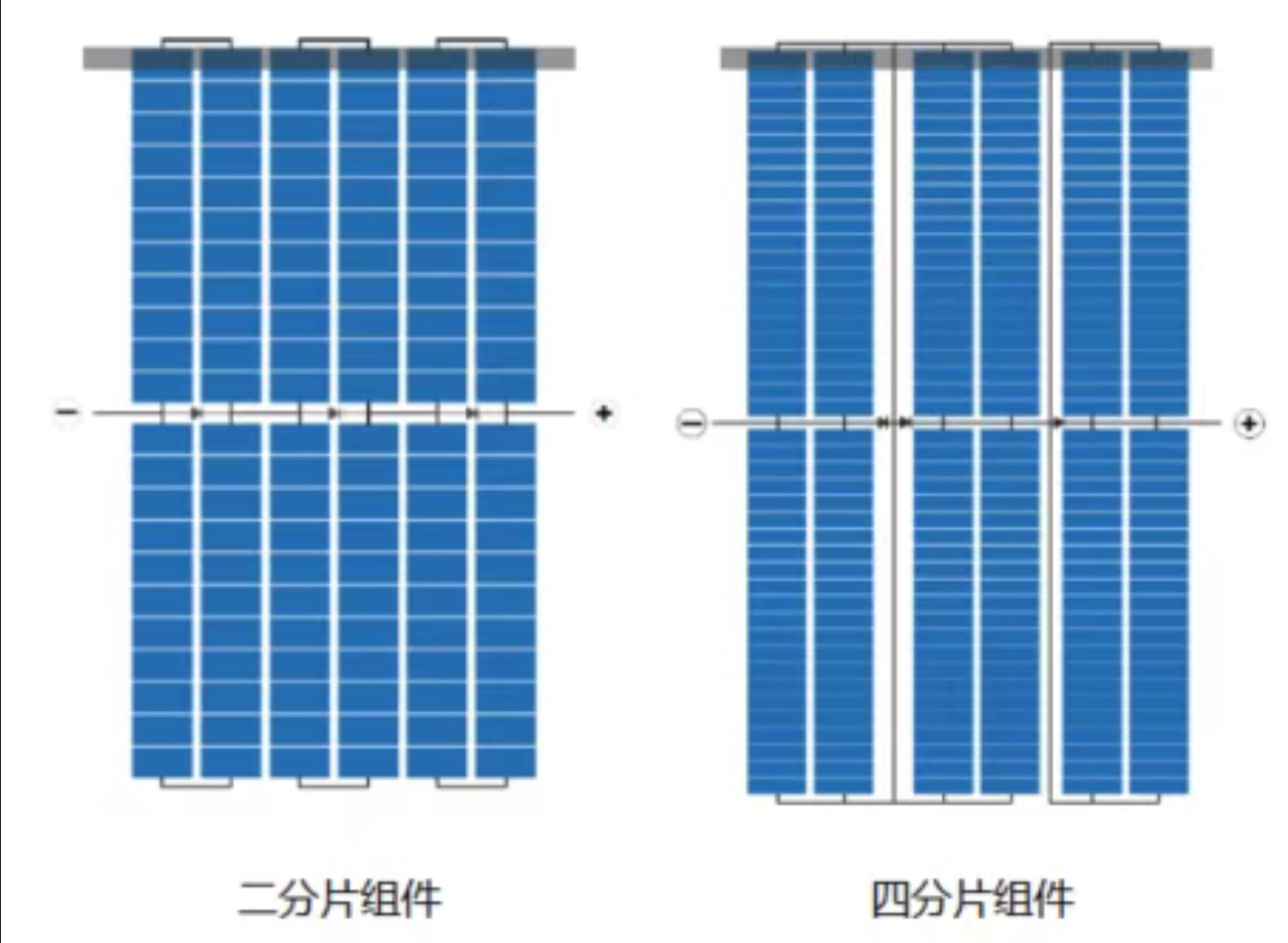

Why insist on quarter-slicing? I believe there are two core pain points: one is that power outputs across similar wafer sizes are largely comparable, offering no absolute competitive edge; the other is the current nightmare of large silicon wafers. When current exceeds 18A across a full 210mm wafer, Joule's Law dictates that power dissipation skyrockets quadratically. Half-wafer technology falls short, and three-wafer solutions are merely transitional—four-wafer cutting is the ultimate solution. This approach reduces current per wafer to 4.6A, slashing internal losses to just 1/16th of the original value. This is the foundational logic behind achieving 770W power output.

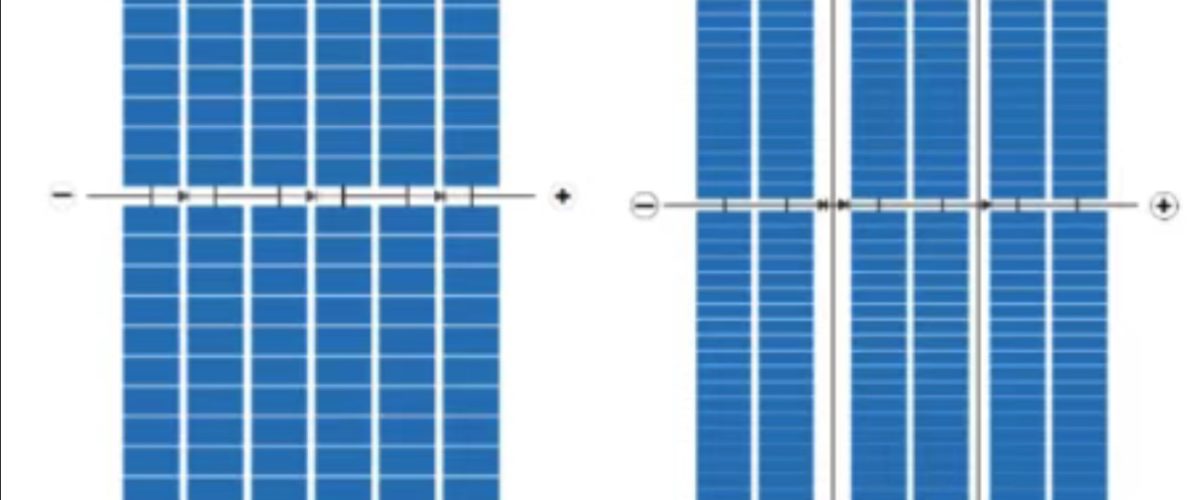

However, quadruple-slicing is a double-edged sword. Doubling the number of cuts directly increases the breakage rate, while slicing also causes edge composite losses, reducing the cell's bending strength by 30%. In reality, the breakage rate can be gradually lowered through ramping up production, but the main challenges lie in composite losses and the 30% reduction in bending strength—issues that once deterred the entire industry. Until Tongwei's TPE edge passivation technology and JinkoSolar's patented “three-series-four-parallel” configuration emerged: Tongwei employs a nanoscale passivation film to repair cutting damage, nearly eliminating efficiency loss; JinkoSolar optimizes circuit architecture to ensure quad-cut cell currents perfectly match existing inverters, avoiding system retrofitting hassles. I haven't seen quad-cell modules myself, but as you can see from the diagram above, quad-cell designs feature large jumpers. Jumpers are prone to cold soldering—even if they hold initially, long-term reliability is uncertain. Optimizing the design to eliminate jumpers entirely would be ideal. Currently, jumper technology isn't quite ready for widespread adoption (in my humble opinion).

According to reports, Tongwei plans for quad-cell production to account for over 60% of its capacity by 2026, while JinkoSolar is also fully deploying quad-cell technology. In fact, all photovoltaic module manufacturers are gearing up for this shift. TrendForce forecasts that quad-cell modules will reach a 45% market share by 2026, with domestic photovoltaic module manufacturers proliferating across the industry.

Quad-sharding is a product of technological competition and innovation, fundamentally a battle for technical influence. What are your thoughts on quad-sharding? Feel free to share your perspective in the comments section!